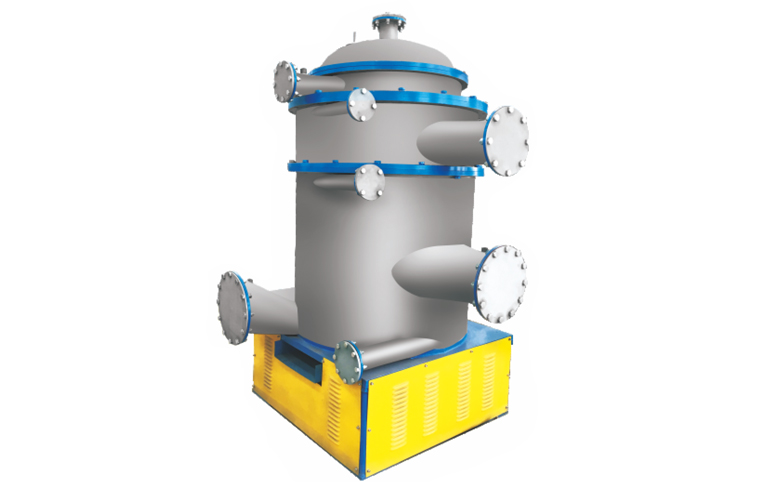

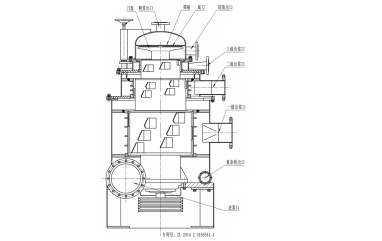

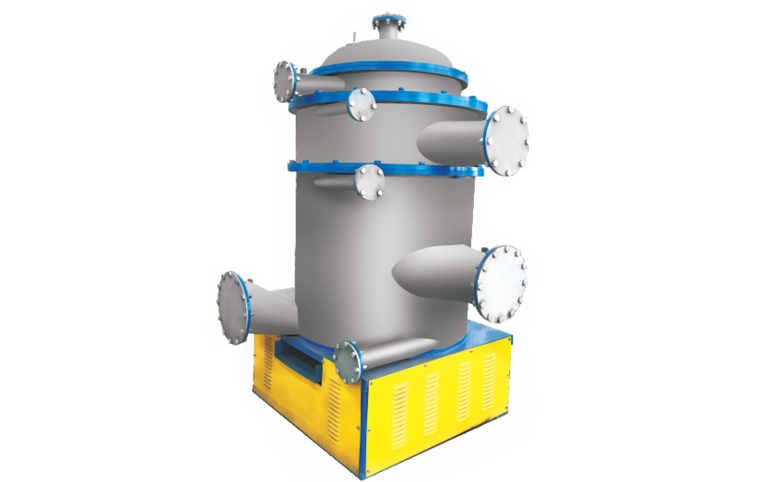

Multi-level sieve (screening impurities at the same time on the long, medium and short fiber grading)

Type:Super multistage screening system

- Times:

- Date:2018/03/24

- Inquiry

In the OCC waste paper processing production line, the manufacturer has to deal with the slurry for long, medium and short fiber according to the production process, and the advantages are especially significant.

The traditional grading sieve is a separate pressure screen. The pulp is filtered through the bottom and screened by the sieve drum to be short fiber. The remaining size is not screened by the sieve drum, and it is continuously rising to the top of the sieve to discharge from the top. After removing the sand and entering the two sections of pressure screen, the pulp is used as long fiber, and the second part of the sieve residue needs to be processed through three sections. The process is tedious, costly and complex.

Based on domestic production practice and absorbing foreign advanced technology, our company has developed a new generation of pulp fiber sizing screen. Three screening zones for long, medium and short fibers in a classifying sieve have a significant effect in actual production. In production, according to the technological requirements, can be long, medium and short fiber classification, pulp by entering a screening area at the bottom of the screen after a good pulp as short fibers, the residual slurry mixing dilution water entering secondary screening area selection, screening after good pulp can be used as long fiber or fiber. The residual coarse slurry mixed diluent water enters into three segments to screen. After screening, the slurry can also be used as long fiber. The tailings are discharged from the top.

Product advantage:

1 covers an area of small, simple operation, streamline process.

2 low power consumption, only about 40% of the traditional process.

3 fiber classification clear, tail slag can be straight row, almost no fiber.

4 one-time investment less.

5 low maintenance costs.