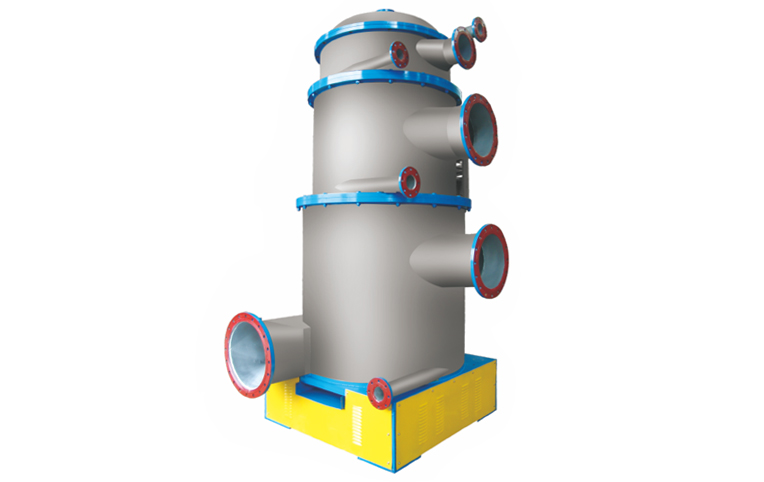

Multistage pressure screen

Type:Super multistage screening system

- Times:

- Date:2018/03/24

- Inquiry

As an important screening equipment in the process of pulping, pressure screen is indispensable in production. In recent years, the paper industry competition has become more and more cruel, requiring high yield and low consumption of low carbon environmental protection production pulping. Traditional pressure screen is not suitable for paper factory now operation requirements, our company according to the operation condition of the traditional pressure screen, and through digesting and absorbing foreign technology, according to the pulp in different technical requirements, developed a multistage pressure screen (including: multistage pressure screen, multistage sizing screen, multilevel filter separator) and other screening equipment.

Multi-stage pressure screen (hole screen, slit screen) is introduced: multi-stage pressure screen is used to replace the traditional pressure screening process. In the multistage screen to complete the screening, tailings straight line.

Multistage pressure screen (seam hole sieve, sieve) principle features: two to four commonly used multistage pressure screen screen area to screen size (currently used mostly three screening area) into pulp, the bottom row of slag, and at the bottom of the top row of light slag flow structure. Each screening area has a good pulp outlet. According to the type of slurry and process requirements, the good pulp of each outlet can be used reasonably.

Paste into the slurry through the bottom and after the first screening area first, after filtering residual slurry mixing dilution water rose to the second screening area, secondary screening of slurry mixture after secondary dilution water entering the third screen area. Three sections of screening good pulp can also be recycled back to the previous flow. Tail slag straight line, fiber loss low, in the actual operation of multiple paper mill effect is very obvious.

Product advantage:

1 covers an area of small, a multi-stage screen to complete the screening process of more than the traditional screen.

2 simplify the pulping process, reduce the slurry pool, slurry pump and pipeline settings, reduce investment costs.

3 low power consumption, only about 40%-50% of the traditional screening.

4 straight slag, ber loss, ber loss rate can be reduced to less than 1%.

5 simple operation,low maintenance cost.

6 rotor is equipped with anti impurity, clew winding function, wing with guide groove to further improve the screening ef ciency of small impurities damage.

7 self cleaning function to prevent clogging of the screen drum.

Technical Parameters

Screening area | LDS(0.4+0.2+0.15) | LDS(0.6+0.3+0.15) | LDS(0.8+0.3+0.15) | LDS(1.2+0.4+0.15) | LDS(1.5+0.6+0.3) | LDS(2+0.8+0.3) | LDS(3+1+0.3) | LDS(3.5+1.2+0.6) | LDS(4+1.2+0.5) | LDS(5+2+0.6) | LDS(6+4+1.2) |

| Filter series | 3级 | ||||||||||

| Sift concentration(%) | 0.8-2% | ||||||||||

| Maximum production capacity(T/D) | 60 | 90 | 120 | 3180 | 250 | 370 | 420 | 500 | 700 | 900 | 1200 |

| Hole sieve concentration(%) | 2-4% | ||||||||||

| Maximum production capacity(T/D) | 120 | 280 | 280 | 350 | 480 | 600 | 800 | 950 | 1100 | 1500 | 2000 |

| Motor Power(kW) | 11-18.5 | 30-37 | 30-37 | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-132 | 132-160 | 160-185 |