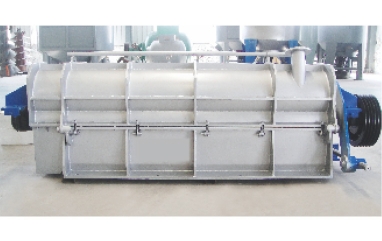

Upflow pressure screen

Type:Deinking equipment

- Times:

- Date:2018/03/24

- Inquiry

The equipment used at the bottom of the bottom row into the slurry, slag, top light slag upflow structure for waste paper pulp screening, fine screening and screening material before the paper machine.

1. low feed pressure required.

2. light impurities and air are rapidly expelled from the top end of the slurry.

3. heavy impurities are discharged into the heavy slag tank at the bottom of the screen to prevent wear and damage of the rotor and sieve drum and reduce downtime.The efficiency of.

4. liter flow screen is high, the residence time of impurities in screening area is short, and the possibility of impurity circulation is reduced remarkably.

| Model | LUV0.5 | LUV1.2 | LUV2.0 | LUV3.0 | LUV4.0 | LUV5.0 |

| Screening area(m ) | 0.5 | 1.2 | 2 | 3 | 4 | 5 |

| In and out of the pulp concentration(%) | 0.2-5.0 | |||||

| Sieve seam size(mm) | 0.15-0.55 | |||||

| Mesh specifications(mm) | 1.2-5.0 | |||||

| Production capacity(t/d) | 20-30 | 40-60 | 80-100 | 100-250 | 160-450 | 200-500 |

| Equipped with power(Kw) | 22/37 | 45/75 | 75/100 | 90/132 | 160/220 | 185/315 |